List of Contents

Rigid Packaging Market Size and Forecast 2025 to 2034

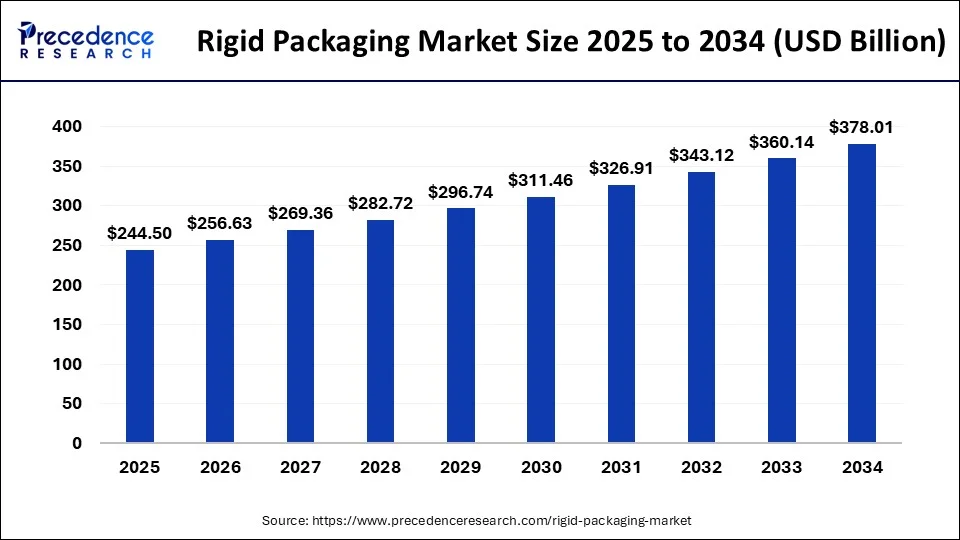

The global rigid packaging market size was estimated at USD 232.95 billion in 2024 and is anticipated to reach around USD 378.01 billion by 2034, expanding at a CAGR of 4.96% between 2025 and 2034.

Rigid Packaging Market Key Takeaways

- In terms of revenue, the rigid packaging market is valued at $244.50 billion in 2025.

- It is projected to reach $378.01 billion by 2034.

- The rigid packaging market is expected to grow at a CAGR of 4.96% from 2025 to 2034.

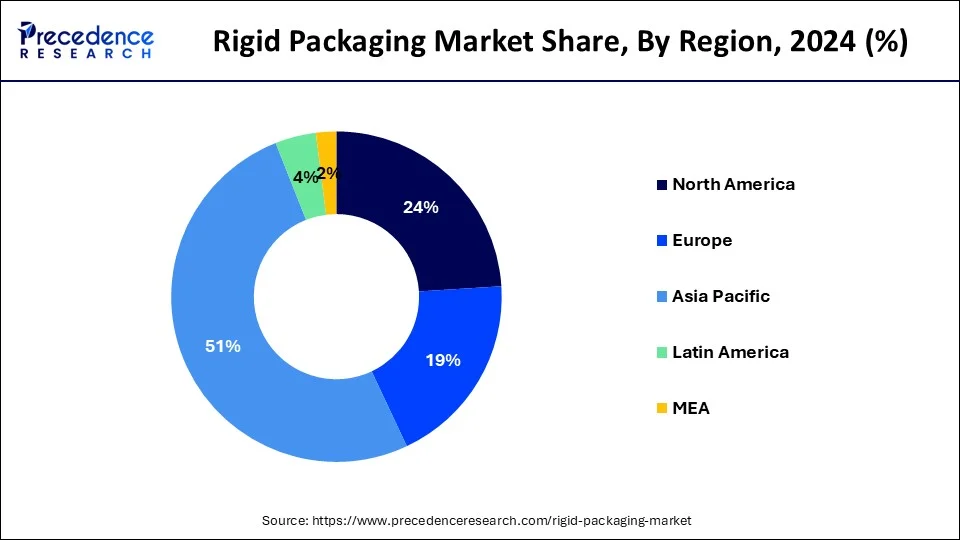

- Asia Pacific generated more than 51% of the revenue share in 2024.

- North America is expected to expand at the fastest CAGR between 2025 and 2034.

- By Material, the plastics segment is expected to register the highest market share from 2025 to 2034.

- By Material, the paper & paperboard segment is predicted to grow at the highest CAGR from 2025 to 2034.

- By Application, the food & beverages segment contributed more than 59% of the market share in 2024.

Asia Pacific Rigid Packaging Market Size and Growth 2025 to 2034

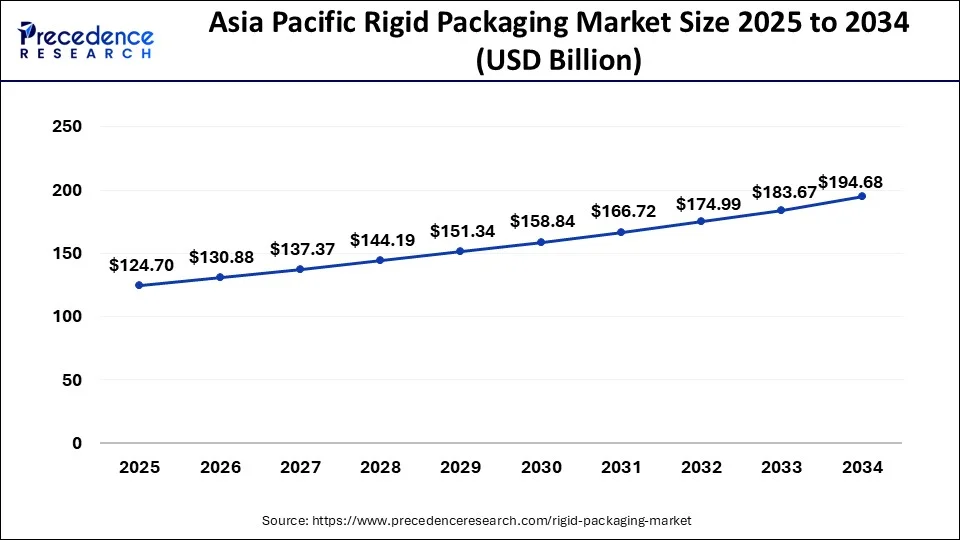

The Asia pacific rigid packaging market size accounted at USD 118.80 billion in 2024 and is expected to be worth around USD 194.68 billion by 2034, growing at a CAGR of 5.06% between 2025 and 2034.

The Asia Pacific is expected to capture the largest market share over the forecast period.The growth in the region is attributed to the growing food & beverages and personal care & cosmetics industry particularly in India and China. The most recent analysis from Euromonitor International indicates that $88 billion worth of beauty and personal care products were sold in China in 2021, an increase of 10% from the previous year. The China Chain Store & Franchise Association also reports that the food and beverage market in China reached $595 billion in 2019, up 7.8% from 2018. Thus, the aforementioned facts support the market growth over the forecast period.

Asia Pacific is dominating the rigid packaging market. Factors influencing the region to grow are urbanization, industrialization, and an increase in the food and beverages sector. Mainly, China's contribution to the highest market share and the emerging economies expands the market globally.

North America is expected to grow at a significant rate over the forecast period.The robust advancements in the rigid thermoform plastic packaging industry are responsible for this region's expansion. Numerous benefits of thermoforming include its lower cost and adaptability. The rigid thermoform plastic packaging industry has seen enormous growth in product manufacture, creating a sizable client base that is fueling the expansion of the North American rigid packaging market.

Europe is expected to grow at a fast rate during the forecast periodbecause the food and beverage industry has a rising requirement for rigid packaging solutions. Due to the presence of some of the biggest food and beverage companies in the region, there will certainly be an increase in the need for rigid packaging solutions. Additionally, the rising demand for personal care and cosmetic products from this region is anticipated to fuel market revenue growth. For instance, the manufacture of body care products and perfumes in Germany generated revenues of USD 4223 million and USD 3020 million respectively in 2022, according to the Federal Statistical Office. Therefore, the aforementioned stats drive the market expansion over the forecast period.

Market Overview

Packaging is referred to as rigid if it cannot be bent or forced out of shape. It is known for its strength and lack of flexibility while also providing things with support and structure. Plastic bottles and boxes, aluminum cans, glass jars, and corrugated and paperboard boxes are a few examples of rigid packaging materials. Cereal boxes, glass liquor bottles, soup cans, and detergent bottles are only a few examples of recognized uses. Flexible packaging protects products from severe heat, corrosion, moisture, and other environmental harmful forces. Rigid packaging is a suitable substitute. With regard to the increased attention of stakeholders, there are quite a few innovations occurring in that field as well as several product advancements.

In rigid packaging solutions, new plastic grades and versions are used to enhance the quality of the packaging that safeguards against external risks. The market is being driven by various factors including the growing food & beverages industry, increasing personal care and cosmetic sector, rising R&D investments, growing product launches, and increasing e-commerce industry.

According to the Australian Institute of Health and Welfare, Australia spent a predicted $220.9 billion on health-related products and services in 2020–21, or $8,617 per person on average. Total health spending (recurrent and capital) increased by 7.1% in real terms over 2019–20 (inflation-adjusted). Even while this growth was higher than the 3.4% average annual growth rate for the ten years leading up to 2020–21, it primarily reflected a return to pre–pandemic health spending trends, especially for non–government spending. Australia's health expenditures made up 10.7% of the country's GDP in 2020–21, an increase of 0.5 percentage points from 2019–20. The overall health spending in 2020–21 was $156 billion, or 70%, supported by the government, and the remaining 29%, or $64.9 billion, was funded by non–government sources.

Market Scope

| Report Coverage | Details |

| Market Size in 2024 | USD 232.95 Billion |

| Market Size in 2025 | USD 244.50 Billion |

| Market Size by 2034 | USD 244.5 Billion |

| Growth Rate from 2025 to 2034 | CAGR of 4.96% |

| Largest Market | Asia Pacific |

| Fastest Growing Market | North America |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | By Material and By Application |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Driver

Growing demand from the healthcare industry

The governments of developing nations in many regions are investing in modernizing the healthcare systems, particularly in the era of a pandemic. As rigid plastic packaging is durable, hygienic, transparent, and lightweight, it protects medicines from contamination and is ideal for keeping medical products including tablets, syringes, surgical supplies, syrups and other products. Rigid packaging is expected to become more popular on a global scale as a result of the expanding healthcare industry. For instance, as per the China National Health Commission, the total size of China's healthcare industry will reach $2.39 trillion by 2030. Thus, the increasing healthcare industry in developing nations is expected to propel the market growth over the forecast period.

Restraints

Environmental impact of plastics

High-density polyethylene (HDPE), expanded polystyrene (EPS), polyethylene terephthalate (PET), and polyvinyl chloride (PVC) are the polymers that are most frequently utilized in the packaging industry. Different industries use rigid plastic packaging to protect and sustainably store packed goods like industrial equipment, food, and medical supplies. Recycling, reusing, and segregating plastic garbage is the main issue posed by these plastics. Plastic packaging materials can take up to a thousand years to breakdown in landfills, causing pollution of the land and water. Furthermore, plastics lose mechanical strength when exposed to direct sunshine, while thermoplastics creep and soften at room temperature. Thus, the environmental impact of plastics on environment is one of the major restraints that hamper the market growth during the forecast period.

Opportunities

Increasing uses of rigid packaging in personal care and cosmetic industry

Rigid plastic packaging is used in the personal care and cosmetics sector to package goods for use in sun care, oral care, skin care, body care, perfume, decorative cosmetics, and hair care. This gives the goods frictionless storage and a longer shelf life. In emerging nations, the market for cosmetics and personal care products is expanding quickly, which is driving up demand for rigid plastic packaging. For instance, the Malaysian International Trade Administration estimates that the global market for cosmetics and personal care would expand at a compound annual growth rate of 4% by 2025. Thereby, this is expected to drive the market growth over the forecast period.

Technological Advancement

Technological advancement in the rigid packaging market features smart packaging, advanced materials, manufacturing processes, design innovations, automation and robotics, and AI and machine learning. Innovative technological methods used in material processing include lightweight composites, which use durable composite materials to reduce shipping costs and material usage. Another is biodegradable plastics, which promotes environmental concern and the practice of sustainable packaging.

Advancements in manufacturing processes include multi-material molding, injection molding, blow molding, and extrusion. Extrusion, blow molding, and injection molding a traditional methods that can be converted into advancements and automation to accelerate production efficiency and enhance quality. The multi-material molding process is used in creative packaging.

Smart packaging consists of QR codes and RFID, AI and IoT, and sensors and active packaging. AI and IoT help in monitoring, real-time tracking, and analyzing products by providing data on environmental conditions and the quality of the product. Sensors in the rigid packaging market monitor humidity, temperature inside the package to ensure product safety. QR codes and RFID trace products and authenticate the verification process.

Material Insights

Based on the material, the global rigid packaging market is segmented into plastic, metal, paper & paperboard, glass and bioplastic. The plastics segment is expected to capture the largest market share over the forecast period. The widespread use of polyethylene terephthalate (PET) bottles in a variety of sectors, including the food, beverage, and pharmaceutical industries, is responsible for this increase. The rigid thermoform plastic packaging industry is supported by thermoforming due to its advantages. The U.S. Food And Drug Administration (FDA) has approved the widespread use of polystyrene in packaging, which can reduce the risk of foodborne disease in households and is fueling this market's expansion.

On the other hand, paper & paperboard segment is growing at the highest CAGR during the projection period. Paper containers, also referred to as paper packaging, are a high-efficient and affordable alternative that people can use to move, carry, and store a variety of things. Paper-based packaging is increasingly being used because it can be customized to match the needs of a particular product or consumer and is designed to be strong yet lightweight. Moreover, the use of paper-based packaging will contribute to a sustainable, safe, and healthy environment, among many other advantages because it is made from renewable resources. Thus, owing to these properties the segment will drive the market growth.

Application Insights

Based on the application, the global rigid packaging market is divided into food & beverages, pharmaceuticals, personal care, and others. The food & beverages segment is expected to grow at a significant rate over the forecast period.

The containers benefit from the rigid plastic packaging's flavor-absorbing, long-lasting, lightweight, and durable qualities. The food item is kept safe and contaminant-free in rigid plastic packaging containers including bottles, cans, and jars, among others. In developing nations including the United States, Canada, China, India, and other nations, there is a swiftly growing demand for rigid plastic packaging. Demand for rigid plastic packaging is being driven by the food and beverage industry's continued expansion. For instance, the China Chain Store & Franchise Association estimates that the country's food and beverage (F&B) market grew by 7.8% from 2018 to 2019, reaching over US$595 billion.

Additionally, the Food Export Midwest USA reported that the USDA's Office of Agricultural Affairs (OAA) in Rome stated that Italy's food retail sales in 2019 were US$145 billion, an increase of 1% from the previous year. Thus, this is expected to drive the market growth over the forecast period.

Rigid Packaging Market Companies

- Bemis Company, Inc.

- Amcor Limited

- Coveris Holdings S.A

- Reynolds Group Holding

- Berry Plastics Corporation

- Sonoco

- Sealed Air Corporation

- Silgan Holdings, Inc.

- Plastipak Holdings, Inc.

- Consolidated Container Company

- DS Smith PLC

- Ball Corporation

Recent Development

- In April 2025, SCG Packaging invested in rigid packaging businesses in America by focusing on building a production facility. The company's international expansion will benefit the business.

- In April 2025, IPL and Scholler Allibert merged to create a USD 1.4 billion reusable packaging powerhouse. The announcement of a landmark merger to build a formation in reusable plastic packaging is an eco-friendly contribution to the environment.

- In February 2025, Amcor explored the use of Avantium's Releaf product in rigid packaging. Avantium NV has signed a joint development agreement with Amcor Rigid Packaging USA LLC to gain insights into the use of Avantium's plant-based polyethylene furanoate.

- In May 2023, the first paperboard tube with a fiber-based closure has been created by Stora Enso, Blue Ocean Closures, and AISA. Brand owners can enhance the proportion of renewable material in their packaging by using this brand-new, cutting-edge wood fiber approach. The tube's components are all made to be recycled. The tube is made of Natura ShapeTM, a barrier-coated board from Stora Enso, and a screw cap created in partnership with Blue Ocean Closures, with assembly provided by AISA. The solution has the largest fiber content attainable in a tube design—more than 85%. It is anticipated to go on sale in 2024 and be used in cosmetic and personal care products.

- In September 2022,Sonoco officially agreed to buy privately held Danish paper firm Skjern for USD 88 million in cash. As a result of the acquisition, Sonoco will be able to modernize operations across Europe and neighboring regions and boost client production capacity. The purchase is in line with the packaging company's objective of developing the market for sustainable paper and packaging products in Europe while investing in its core business.

- In September 2022,to create DairySeal, a novel PET barrier technology for dairy beverage containers, Amcor Rigid Packaging (ARP) created ClearCor. The bottles are recyclable and their fabrication may use up to 80% recyclable materials. PET film has been used by ARP to produce a barrier that keeps dairy products taste good. The preform's core has a "concentrated capsulation" made by new technology developed by ClearCor, which allows the containers more flexibility and resin options.

Segments Covered in the Report:

By Material

- Plastic

- Metal

- Paper & Paperboard

- Glass

- Bioplastic

By Application

- Food & Beverages

- Pharmaceuticals

- Personal Care

- Others

By Geography

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client